IoT Applications

Predictive Maintenance at EdgeCOM

Views : 9775

Author : Fiona Dai

Update time : 2023-11-22 15:58:12

Predictive maintenance is the process of analyzing the operating conditions of equipment or machine to predict when maintenance should be performed on that asset based on current and historical data patterns.

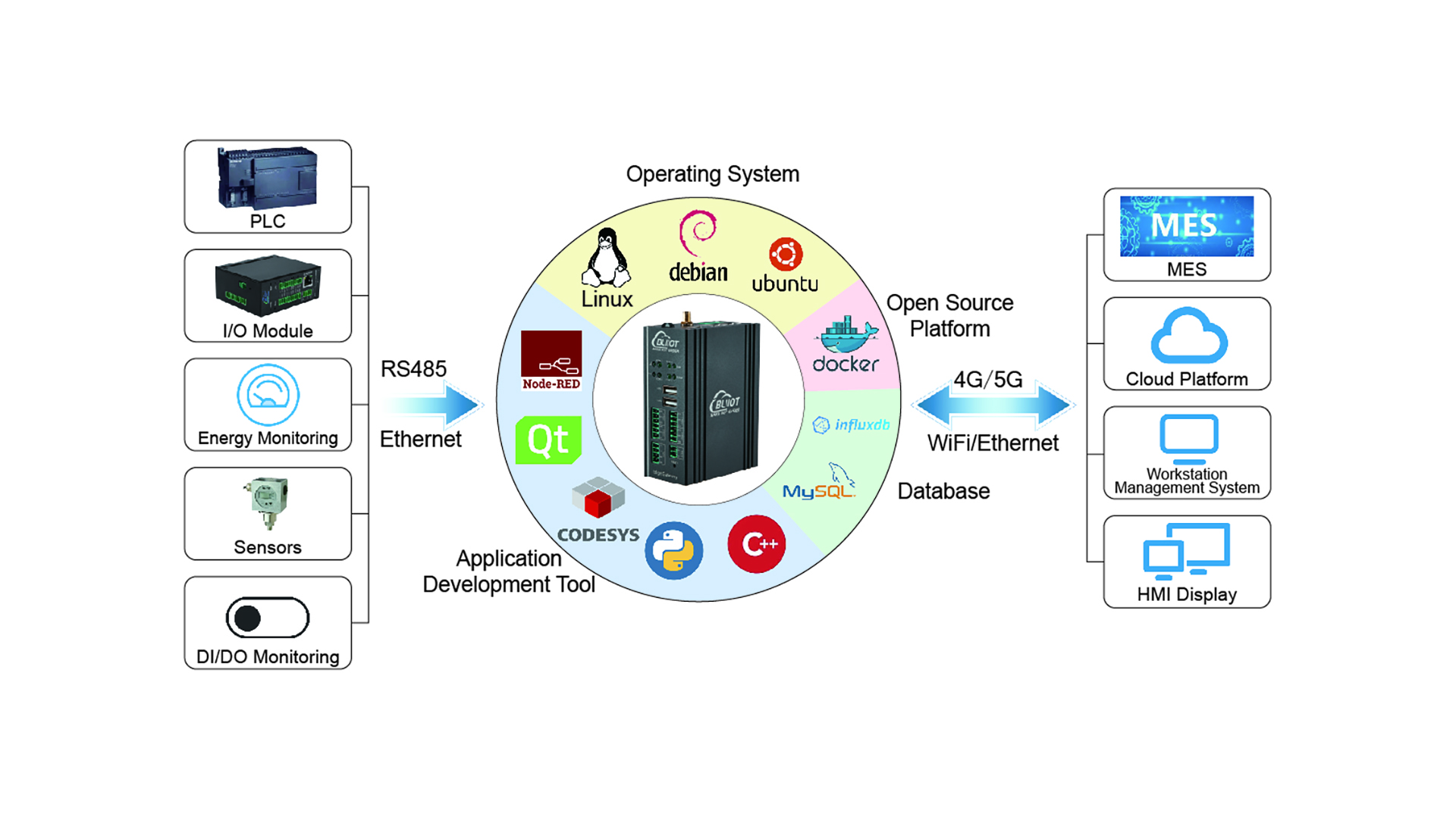

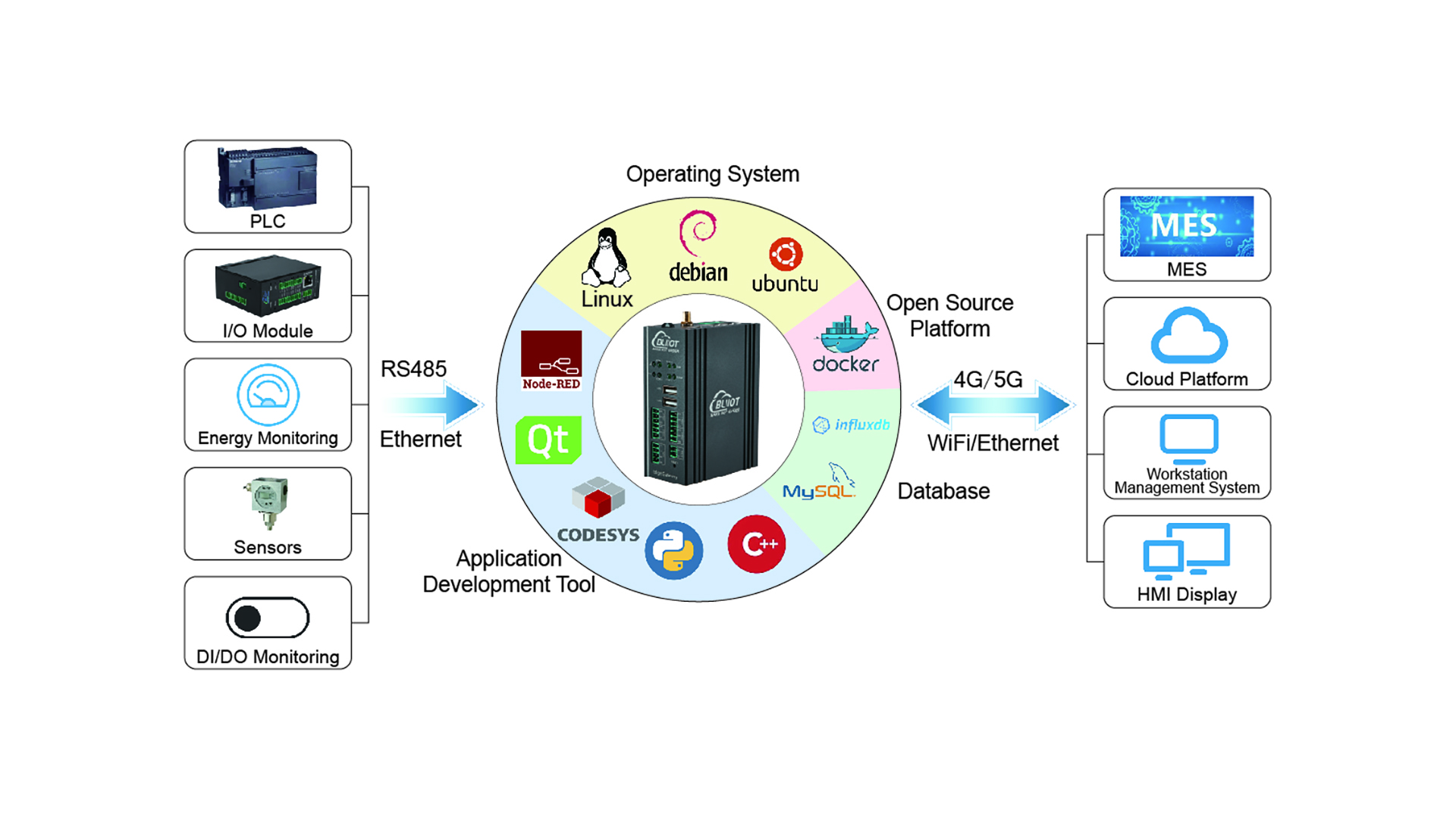

Many companies install IoT sensors such as humidity, temperature, motion, vibration, gases, and other factors that affect machine operation and wear and tear in their equipment to monitor machine conditions.

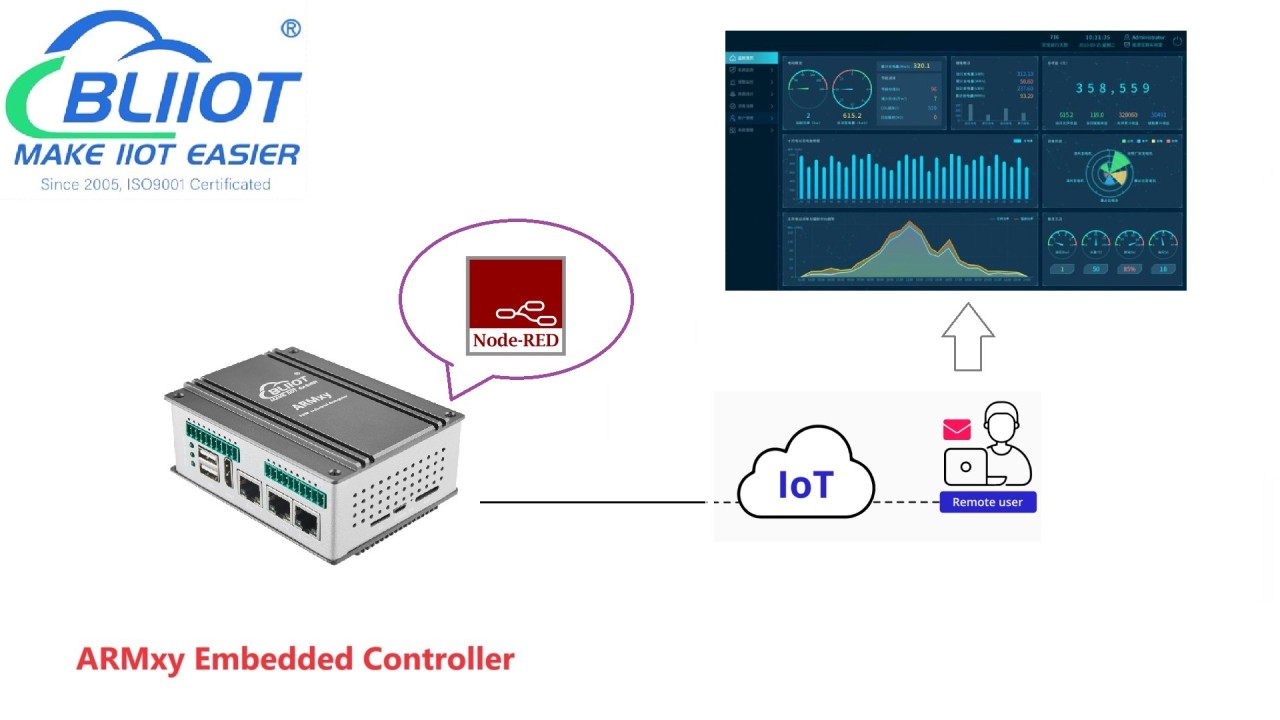

The amount of data that needs to be collected and analyzed in this process is huge, and it is costly to transfer all of this data to the server or cloud, so EdgeCOM can be used to process a portion of the data in real time, reducing the cost of data storage and also improving security. This is critical for industries where a slight delay in response time can lead to disaster.

Benefits of Predictive Maintenance

Reduce Downtime

One of the biggest concerns for manufacturers is reducing unplanned downtime. Even a small period of unplanned downtime can lead to very significant losses. Once an IoT device detects frequent spikes in any variable, managers can take preventative measures to avoid downtime or reduce it, lowering maintenance costs while reducing production time lost to maintenance.

Extend Equipment Life

By monitoring equipment in operation, it is possible to improve the health and extend the average lifespan of connected devices by repairing problems before they become irreparable.

Optimize Maintenance schedules

Knowing in advance which parts are likely to fail allows you to plan ahead for repairs and also to rationalize spare parts ordering based on demand at the right time. Avoid overstocking spare parts or not having them when they are needed.

Many companies install IoT sensors such as humidity, temperature, motion, vibration, gases, and other factors that affect machine operation and wear and tear in their equipment to monitor machine conditions.

The amount of data that needs to be collected and analyzed in this process is huge, and it is costly to transfer all of this data to the server or cloud, so EdgeCOM can be used to process a portion of the data in real time, reducing the cost of data storage and also improving security. This is critical for industries where a slight delay in response time can lead to disaster.

Benefits of Predictive Maintenance

Reduce Downtime

One of the biggest concerns for manufacturers is reducing unplanned downtime. Even a small period of unplanned downtime can lead to very significant losses. Once an IoT device detects frequent spikes in any variable, managers can take preventative measures to avoid downtime or reduce it, lowering maintenance costs while reducing production time lost to maintenance.

Extend Equipment Life

By monitoring equipment in operation, it is possible to improve the health and extend the average lifespan of connected devices by repairing problems before they become irreparable.

Optimize Maintenance schedules

Knowing in advance which parts are likely to fail allows you to plan ahead for repairs and also to rationalize spare parts ordering based on demand at the right time. Avoid overstocking spare parts or not having them when they are needed.