IoT Applications

Remote I/O Improving Power Plant Operation

Views : 5316

Author : Fiona Dai

Update time : 2023-07-25 15:42:27

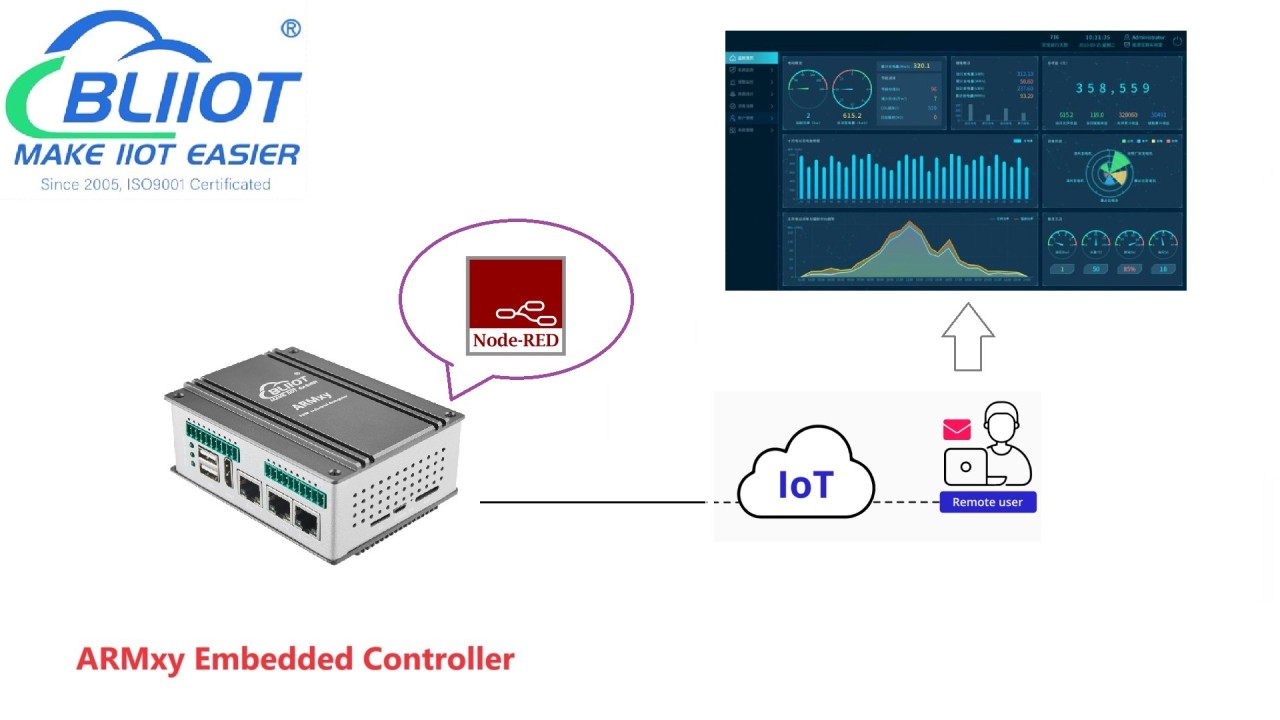

Remote IO module uses Ethernet to transmit data from various industrial control sensors and actuators to hosts for management and monitoring. Modbus TCP Remote IO modules are widely used in various industrial automation solutions to improve operational efficiency, reduce costs, and improve safety.

The Ethernet I/O module can collect data such as environmental parameters and equipment operating status of thermal power plants in real time. Through the analysis and processing of these data, the user can understand the operation of the thermal power plant. Industrial Ethernet I/O module can greatly improve the operating efficiency and reliability of thermal power plants.

BLIIoT Remote I/O module can monitor parameters such as gas flow and water flow in thermal power plants. These parameters are crucial to ensure the normal operation of thermal power plants. Once these parameters change abnormally, you can connect the DO channel on the Ethernet IO module, and the alarm signal will immediately send out an alarm to remind the operator to deal with it. At the same time, BLIIoT Ethernet I/O module can collect data in real time and transmit data to the monitoring system or cloud platform.

Industrial I/O module can monitor the operating status of the equipment in the thermal power plant, such as temperature, pressure, vibration, etc. BLIIoT Ethernet I/O module can detect the failure of the equipment in time, so as to avoid the expansion of losses. In addition, during the maintenance of machinery and equipment, the historical data recorded by the Ethernet I/O module can be used to formulate a more scientific and reasonable maintenance plan, reduce maintenance costs, and improve maintenance efficiency.

BLIIoT Ethernet I/O module can help thermal power plants realize distributed control. We can realize remote control and monitoring of multiple areas of thermal power plants by connecting multiple I/O modules to a network. This can not only reduce the commissioning of the equipment on site, but also strengthen the evaluation of the reliability of the equipment.

The Ethernet I/O module can collect data such as environmental parameters and equipment operating status of thermal power plants in real time. Through the analysis and processing of these data, the user can understand the operation of the thermal power plant. Industrial Ethernet I/O module can greatly improve the operating efficiency and reliability of thermal power plants.

BLIIoT Remote I/O module can monitor parameters such as gas flow and water flow in thermal power plants. These parameters are crucial to ensure the normal operation of thermal power plants. Once these parameters change abnormally, you can connect the DO channel on the Ethernet IO module, and the alarm signal will immediately send out an alarm to remind the operator to deal with it. At the same time, BLIIoT Ethernet I/O module can collect data in real time and transmit data to the monitoring system or cloud platform.

Industrial I/O module can monitor the operating status of the equipment in the thermal power plant, such as temperature, pressure, vibration, etc. BLIIoT Ethernet I/O module can detect the failure of the equipment in time, so as to avoid the expansion of losses. In addition, during the maintenance of machinery and equipment, the historical data recorded by the Ethernet I/O module can be used to formulate a more scientific and reasonable maintenance plan, reduce maintenance costs, and improve maintenance efficiency.

BLIIoT Ethernet I/O module can help thermal power plants realize distributed control. We can realize remote control and monitoring of multiple areas of thermal power plants by connecting multiple I/O modules to a network. This can not only reduce the commissioning of the equipment on site, but also strengthen the evaluation of the reliability of the equipment.